This year’s Brake Safety Week runs August 24–30, bringing intense scrutiny to commercial vehicle brake systems across North America. Powered by CVSA’s Operation Airbrake initiative, it emphasizes drum and rotor condition—crucial for maintaining road safety and avoiding costly out-of-service violations Midwest Carriers+10truckcountry.com+10Kwofpa+10Midwest Carriers+10The BRAKE Report+10The BRAKE Report+10.

Nearly 13% of inspected vehicles were sidelined due to #brakerelated issues last year—so being proactive isn’t just smart—it’s essential Work Truck Online+1.

What Inspectors Focus On

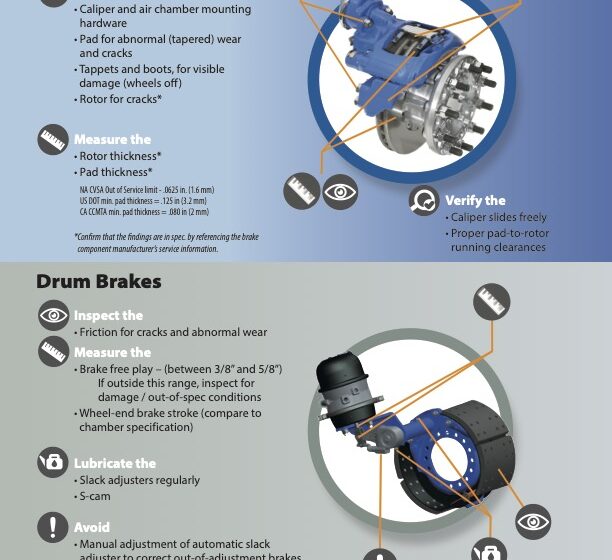

During inspections, certified CVSA inspectors assess:

- Air leaks, pushrod travel, and slack adjuster alignment

- Functionality of warning systems like the ABS Malfunction Indicator Light

- Brake drums and rotors—checking for wear, cracks, or damage U.S. Xpress Inc.+11The BRAKE Report+11The BRAKE Report+11

Any mismatches—broken springs, misadjusted brakes, or worn components—can lead to out-of-service orders… more info

Preparation Tips: Daily, Weekly, Monthly

Daily Checks

Inspect for damaged air brake chambers, loose pushrods, misaligned slack adjusters, and insecure hoses YouTube+8The BRAKE Report+8The BRAKE Report+8.

Weekly Tasks

Conduct a 90–100 psi brake application with wheels chocked and parking brake released to catch air leaks. Check air disc rotors for cracks and drum linings for wear trinitylogistics.com+4The BRAKE Report+4TheTrucker.com+4.

Monthly Maintenance

Check for moisture in your air system, grease S-cam tubes, and lubricate automatic slack adjusters to prevent rust and corrosion The BRAKE Report+3The BRAKE Report+3TheTrucker.com+3.

Note: Air disc brakes simplify maintenance with internal adjustment, whereas drum brakes require measuring brake stroke (distance change at clevis pin) to ensure proper adjustment The BRAKE Report+4The BRAKE Report+4TheTrucker.com+4.

Select the Right Parts for Safety & Compliance

Using OEM-compliant friction materials is crucial—many aftermarket options fall short of reduced stopping distance (RSD) standards and can cause damage to wheel-ends YouTube+4The BRAKE Report+4The BRAKE Report+4.

Upgrade options like Bendix® EnduraSure®‑Pro™ sealed chambers, Bendix® iSense™ Pro for wear alerts, and ADB22X brake pad-rotor pairs help prevent serious issues like stress cracking or uneven wear The BRAKE Report+2The BRAKE Report+2.

Why We Trust Brakes Only Mobile Service

While knowing what to check is vital, who performs the service matters even more—and that’s where #BrakesOnlyMobileService shines:

- On-Site Precision Maintenance — Skilled techs perform inspections and adjustments right at your location; no downtime hauling to the shop.

- Proactive Upgrades — They use OEM-compliant friction, air disc or drum adjustments, and alert systems to stay inspection-ready.

- Preventative Detailing — From seal checks to moisture purge, they ensure your wheel-ends work reliably under pressure.

- Inspection Peace of Mind — With mobile service delivered by trusted pros, you’re ready to pass Brake Safety Week without surprises.

Quick Comparison

| Maintenance Level | What You Do | What #BrakesOnlyMobileService Delivers |

|---|---|---|

| Daily/Weekly Inspections | Catch wear, leaks, misalignment | Expert mobile checks with precision |

| Monthly Upkeep | Greasing, moisture control | Proactive component health and longevity |

| Component Selection | Choose OEM-safe parts | Use of compliant, advanced brake systems |

| Inspection Readiness | Avoid violations | Confidence during Brake Safety Week |

TL DR

- Brake Safety Week 2025 zeroes in on drum and rotor condition—prepare now to avoid violations.

- Regular checks, correct component selection, and proper maintenance are critical.

- #BrakesOnlyMobileService ensures compliant, expert brake service—delivered where and when you need it.

Stay safe, stay compliant—and keep your fleet rolling. Book #BrakesOnlyMobileService today for a worry-free Brake Safety Week.